7 Easy Facts About Sheroz Earthworks Shown

7 Easy Facts About Sheroz Earthworks Shown

Blog Article

Facts About Sheroz Earthworks Uncovered

Table of ContentsNot known Details About Sheroz Earthworks Our Sheroz Earthworks PDFsLittle Known Questions About Sheroz Earthworks.The Only Guide for Sheroz EarthworksThe smart Trick of Sheroz Earthworks That Nobody is Talking About

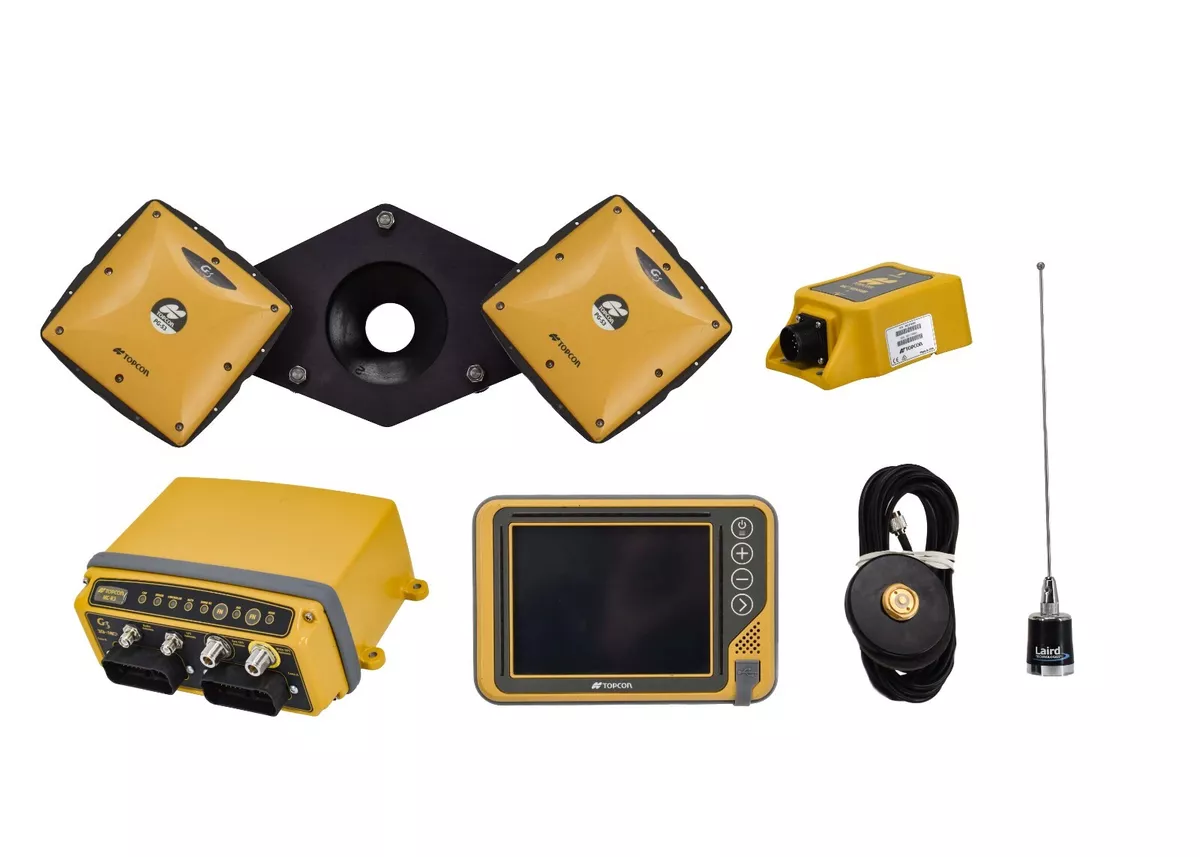

When specialists like Rasch Building and construction apply a quality control system for their dozers, it assists them make fewer blunders when grading. This system continuously keeps an eye on the blade, makes tiny changes to the setting of the dozer blade throughout grading and decreases rework. If the dozer doesn't quality the ground exactly as prepared, the driver can realign the dozer blade to remedy minor mistakes and make accurate adjustments to get to the desired quality.When taking into consideration the acquisition of a grade control system for a dozer, drivers will require training on how to use the system. New operators and experienced professionals need to recognize with the parts of the 3D grade control system, including the equipment (for instance, the sensing units and receivers) and the software application components.

The 7-Minute Rule for Sheroz Earthworks

This consists of quality details, elevation data and other pertinent metrics showed on the LCD screen inside the dozer's taxicab. Last, operator training need to include exactly how to properly manage the dozer blade making use of the 3D quality control system. This aids them comprehend exactly how the system readjusts the blade in reaction to grade variations.

Product financial savings: If the quality is more specific, a contractor may need much less material for the jobsite. Operators might also decrease the need for rework and boost expense financial savings since of labor and products - https://yoomark.com/content/home-sheroz. To get more information concerning exactly how to improve jobsite effectiveness with grade control innovation, explore the offerings from Trimble and comparable companies

Guidance and accuracy control, the base aspects of modern device control for building, have continued to progress since broad productization started in the linked here mid-1990s. However, the value suggestion has actually ended up being also sweeter since, with worth being understood past the roi (ROI) of the general service providers and the total task rate tag for the clients.

8 Simple Techniques For Sheroz Earthworks

The origins of maker control stretch back a century. The Historic Construction Devices Association (HCEA) assumes that the A.W. French & Co. "energy " of the 1920s, a crawler-mounted device that utilized stringline control, may be the really first example and this prior to electronic devices and computing. It was the advent of real-time kinematics (RTK) for GPS in the mid-1990s that brought maker control as we know it to the building website, and coincidentally to precision agriculture.

Then it relocated to accuracy control, such as blade control, and later on propagated to more classes of motorized devices, boosted with further sensor combination. The effect on building and farming has actually been indisputable: productivity gains, much less rework, much more reliable handling of materials, much shorter timelines, site safety and security renovations, and a lot more - https://www.intensedebate.com/people/sherozau. These advantages are as apparent to clients and drivers as they were in the early days of adoption, gains from almost three decades of innovation

Automation is not practically rate; it is likewise about far better control of the tons and stress and anxiety on the equipment and relocating just the appropriate quantity of materials so as not to place a problem on it. (Photo: CHCNAV) These 2 tasks, as each of our talked to professionals testify, represent the lion's share of recognized efficiency gains.

The Basic Principles Of Sheroz Earthworks

"Besides the skid steer systems, there are more excavators manufactured than all the various other equipment kinds incorporated," claimed Daniel Sass, item manager of equipment control at Hemisphere GNSS. "Excavators are the workhorse. And individuals utilize them in different ways, and they utilize various other tools to complement excavators rather in different ways.

By quantity it is excavators and compact excavators. topcon." Numbers aid tell the tale. "In the United States, a minimum of in a three-year period from 2019 to 2022, regarding 253,000 excavators were marketed, for which I have pretty trustworthy data, however only 61,000 dozers and only 7,000 scrapes," Sass stated

If you most likely to Europe, where they use excavators for numerous other tasks, the symmetrical effect may be higher." Operators can easily evaluate the ROI of going digital for private tools such as excavators, but component of the incentive can be that general contractors are needing subcontractors to be outfitted and ready to fit right into a more full electronic site.

"A great deal of bigger sites. I wouldn't state everybody mandates it yet, but that it is expanding." "Driver assistance is not only helping somebody cut to quality faster, but is also the finest method to reduce to quality," stated Cameron Clark, earthmoving sector director, Trimble Civil Construction. "Exactly how do you move the material? That straight connections right into performance by just relocating the material you require to move, which additionally corresponds to much less fuel due to the fact that you can do it faster." With operator help, Clark claimed, it is not uncommon to see productivity gains of 30% to 40%, also with unskilled drivers.

Indicators on Sheroz Earthworks You Need To Know

There are substantial gains to be made in operator assistance for less facility heavy devices, such as compactors. "Commonly a contactor will place a much less seasoned driver in the compactor," Clark claimed. "In hand-operated days, to overcome the capacity of under-compaction and missing out on areas, they would certainly produce rather a big overlap, possibly as much as 40% of overlap between courses.

Report this page